How to accurately locate the direction and burial depth of metal pipelines with underground pipeline detectors

In urban construction and maintenance, underground pipeline detectors are indispensable high-tech tools. The TFN brand T6000 series has become an industry benchmark with its advanced electromagnetic induction technology and intelligent design. This article will analyze the principle and operation process of detecting the direction and depth of pipelines.

Core detection principle: electromagnetic induction technology

T6000 transmits electromagnetic signals of specific frequencies to the underground through a transmitter:

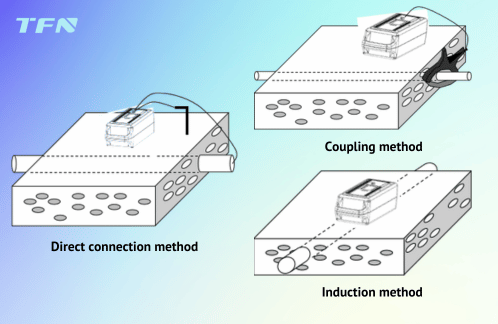

1. Signal application: The signal is loaded to the target pipeline through direct connection (de-energized cable), coupling (live cable) or induction (contactless) to stimulate the pipeline to generate an induced current.

2. Magnetic field radiation: The current propagates along the pipeline and radiates a secondary magnetic field outward, with the intensity decreasing outward from the pipeline as the center.

3. Signal reception: The receiver captures the magnetic field signal and accurately locates it through the peak method (the strongest signal is directly above the pipeline) or the trough method (the weakest signal is the center of the pipeline).

Key advantage: The anti-interference algorithm can reduce the impact of adjacent pipelines or environmental noise.

Detailed explanation of the four-step operation process

Step 1: Signal application (transmitter operation)

Direct connection method (preferred): red clamp is connected to the target cable phase line, black clamp is independently grounded, and the remote ground wire is disconnected to form a loop (impedance must be <3000Ω).

Coupling method (live operation): the coupling clamp is closed to clamp the exposed cable, and high frequency + high-end power is selected to enhance signal coupling.

Induction method (blind test or shallow pipeline): the transmitter is close to the ground, and the built-in antenna transmits high-frequency signals (depth ≤10 meters).

Step 2: Path tracking (receiver operation)

1. Turn on the receiver and select the peak mode, and adjust the gain to 60dB.

2. Move along the predicted path and observe the signal strength bar and digital value (00.0-99.9):

Peak method: The signal peak point is directly above the pipeline, and the sound prompt is the most urgent.

Valley method: The signal valley point corresponds to the center of the pipeline, and the path is verified with the arrow direction.

3. Use the current direction function (SS frequency):

The forward current displays a "+" sign (phase -45°~45°), and the reverse current displays a "-" sign (phase -135°~225°), eliminating crosstalk signals.

Step 3: Depth measurement

Direct reading method (real-time display):

When the receiver is placed above the pipeline and the compass points directly forward, the depth (unit: meter) and current value (unit: mA) are directly displayed in the upper left corner of the screen.

80% method (complex environment):

1. Record the signal value directly above the pipeline (such as 85.0);

2. Calculate the 80% value (85×0.8=68.0);

3. Move horizontally until the signal drops to 68.0. The distance between the two points is the burial depth.

Step 4: Blind measurement of unknown pipelines (induction method extension)

Surface measurement method: The transmitter and receiver are parallel and slowly moved 7 meters apart. There must be a pipeline below the point where the signal suddenly increases. It is suitable for large-scale surveys.

Point measurement method: The transmitter is the center of the circle, and the receiver rotates in a circle with a radius of 7 meters. The line connecting the signal peak points is the direction of the pipeline, which is suitable for precise positioning.

Application scenarios and advantages

T6000 performs well in the following areas:

Municipal construction: avoid water supply, gas, and power pipelines to ensure excavation safety.

Troubleshooting: locate cable short circuit points or damaged locations.

Pipeline network mapping: draw underground pipeline distribution maps with an accuracy of ±5% burial depth + 2.5cm positioning.

Emergency repair: quickly identify buried pipelines and shorten repair time.

Safety tips:

Operators must undergo professional training and strictly follow grounding specifications;

Avoid using in flammable and explosive environments;

Lithium batteries require a dedicated charger, and used batteries must be disposed of in accordance with environmental protection regulations.

Technical innovations

Multi-frequency output (3-frequency synchronization): adapt to pipelines of different materials and depths.

Intelligent matching: The transmitter automatically detects impedance and optimizes signal strength.

Human-computer interaction: Color compass navigation and sound intensity feedback reduce operator fatigue.

Conclusion

TFN T6000 underground pipeline detector transforms electromagnetic technology into an intuitive operating experience. Its precise direction and depth detection capabilities have become the "perspective eye" for urban underground space management. Combining standardized operations with scenario-based applications can greatly improve the efficiency and safety of pipeline operation and maintenance.