How does XRF spectrometer affect the accuracy of metal material sample measurement?

X-ray fluorescence spectrometer (XRF for short) is a technology widely used in elemental analysis and chemical analysis, especially in the measurement of metal materials. It generates X-ray fluorescence by exciting the elements in the sample, and then analyzes the types and contents of these elements. However, when measuring metal material samples, the accuracy of XRF metal spectrometer is affected by many factors, which will be analyzed in detail below.

1. Technical Principles and Features

XRF spectrometer is mainly composed of an excitation source (X-ray tube) and a detection system. The excitation source generates incident X-rays, which interact with the sample to be measured and excite the elements in the sample to generate X-ray fluorescence (secondary X-rays). The detection system measures the energy and quantity of these secondary X-rays, and converts this information into the types and contents of each element in the sample through software. XRF technology has the characteristics of fast analysis speed, wide measurement range, and non-destructiveness, and is particularly suitable for rapid analysis of metal materials.

2. Factors affecting accuracy

Instrument calibration: The accuracy and reliability of the instrument depend largely on regular calibration. Calibration with standard samples can ensure that the instrument's measurement results are accurate. If the instrument is not calibrated or the calibration is inaccurate, it will lead to deviations in the measurement results.

Sample preparation: The preparation of the sample has a great influence on the test results. The flatness, thickness and uniformity of the sample surface will affect the measurement results. For irregular or uneven samples, additional processing, such as polishing or grinding, may be required to ensure the accuracy of the measurement.

Background interference: Other elements in the sample may produce background interference, affecting the measurement of the target element. Modern XRF instruments usually have a background subtraction function to reduce this interference, but the effect and accuracy of the function will also affect the final measurement results.

Measurement conditions: Environmental conditions (such as temperature, humidity) and instrument parameters (such as the power of the X-ray source, measurement time) during the test will also affect the accuracy of the results. For example, changes in temperature and humidity may cause unstable instrument performance, thereby affecting the measurement results.

Element characteristics: XRF is less sensitive to light elements, such as carbon, nitrogen, oxygen, etc., because these elements have low X-ray yields. For the analysis of light element content in metal materials, the accuracy of XRF may be limited.

Matrix effect: The matrix elements in the sample may affect the detection results of the target elements. The matrix effect refers to the interference of the presence of other elements in the sample on the measurement results of the target elements, which needs to be corrected to improve the accuracy.

Quantitative analysis requires standard samples: XRF quantitative analysis usually requires standard samples as reference. If the standard sample is inaccurate or differs greatly from the actual sample, it will lead to deviations in the measurement results.

3. Measures to improve accuracy

Regular calibration: Use standard samples to calibrate the instrument regularly to ensure the accuracy of the measurement results.

Optimize sample preparation: Ensure that the sample surface is flat and uniform, and polish or grind it when necessary.

Background subtraction: Use the background subtraction function of the instrument to reduce the interference of other elements.

Environmental control: Keep the test environment stable to avoid the influence of changes in temperature, humidity, etc. on the results.

Multi-point measurement: For uneven samples, perform multi-point measurements and take the average value to improve accuracy.

Correct matrix effect: By correcting the matrix effect, reduce the influence of other elements in the sample on the measurement results of the target element.

Through these measures, errors can be minimized and the accuracy of XRF spectrometers in the measurement of metal material samples can be improved.

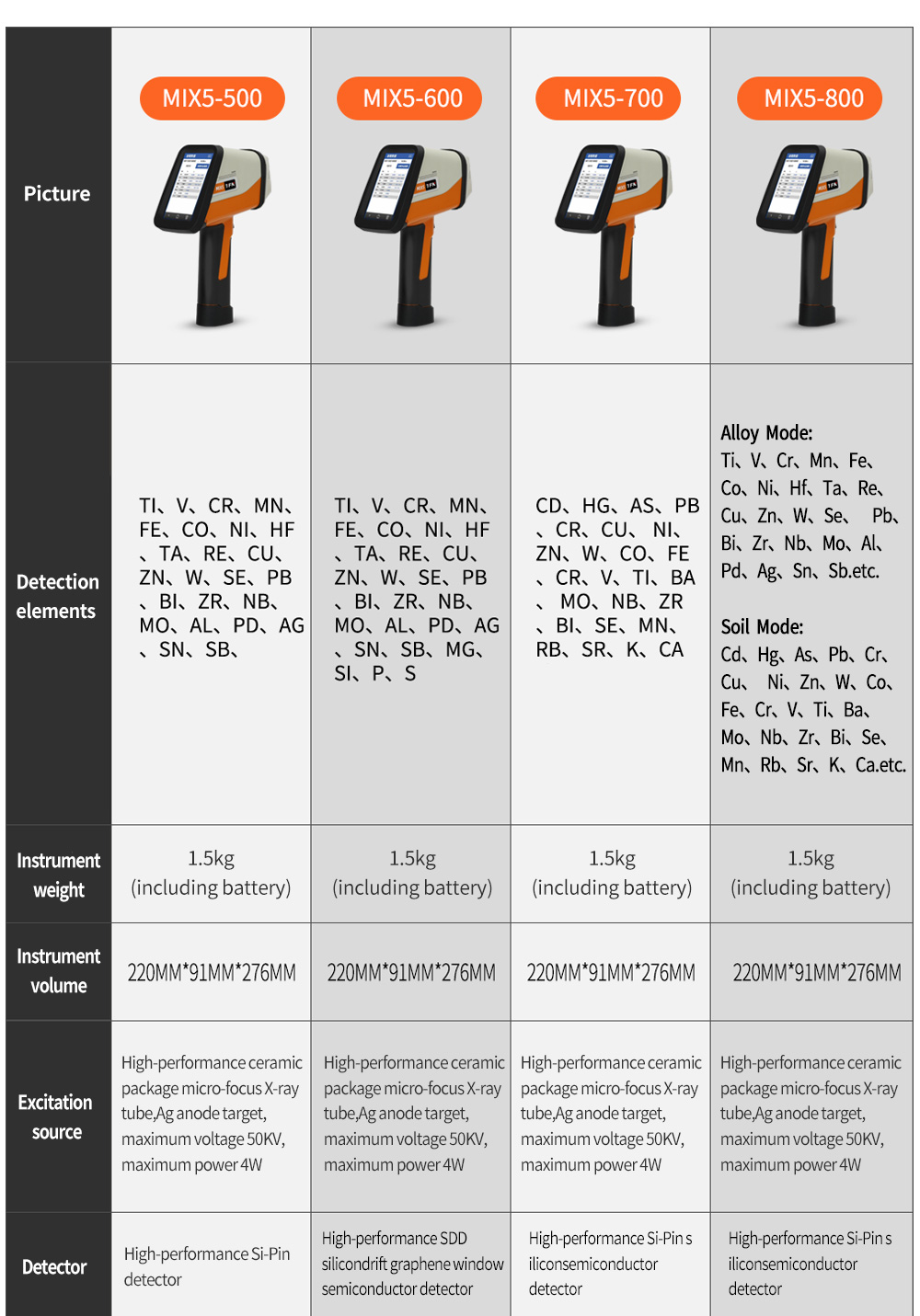

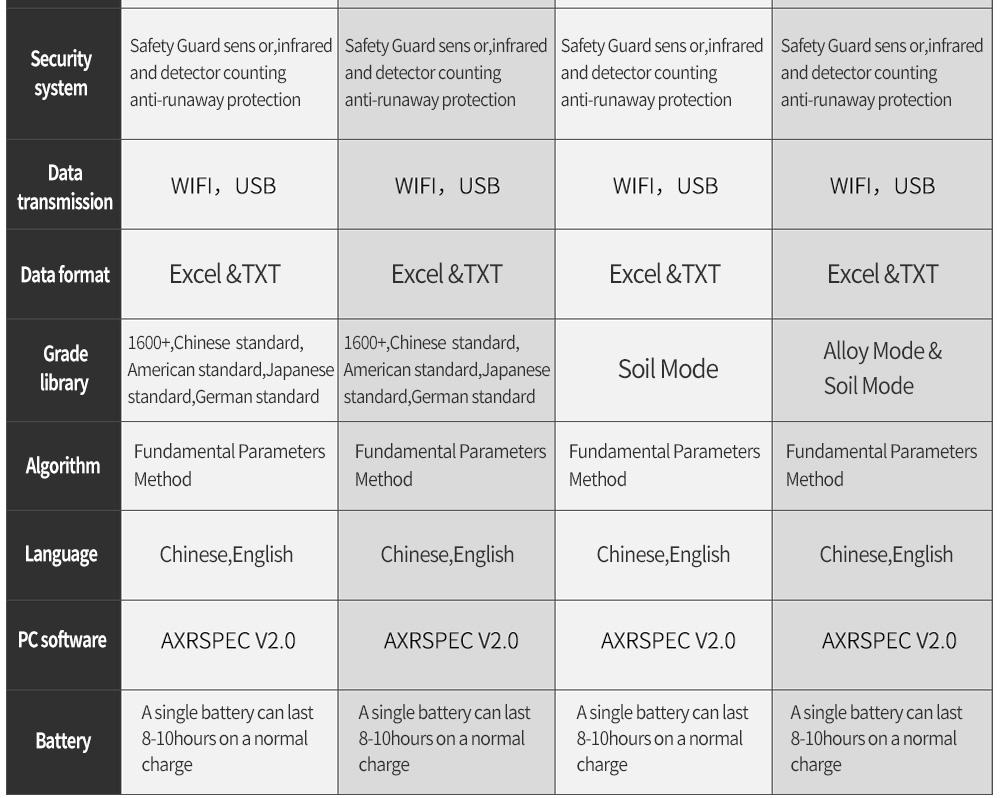

TFN MIX5 XRF spectrometer can quickly, non-destructively and accurately analyze alloy elements in metal materials, with the characteristics of high precision, high stability and low detection limit. It has a built-in intelligent data analysis system, is easy to operate, and supports a variety of data processing methods. The instrument can help users optimize process flow, improve production efficiency, ensure product quality, and achieve effective use of resources.

If you are interested in TFN MIX5 XRF spectrometer, please contact TFN sales team:

Email: info@tfngj.com

WhatsApp: +86-18765219251

Facebook: https://www.facebook.com/tfnfate/